Optimal Polycarbonate Thickness for Greenhouses

Choosing the optimal polycarbonate thickness for greenhouse glazing in the United Kingdom requires balancing insulation, light transmission, durability and cost. Polycarbonate is a lightweight, impact-resistant thermoplastic used widely as an alternative to glass and horticultural polyethylene, and its performance varies with format and thickness.

This section sets out the key factors gardeners and growers should weigh: thermal performance (R-value and U-value), visible light and PAR transmission, structural strength against wind, snow and hail, UV protection, light diffusion, service life and upfront expense. These considerations determine the ideal polycarbonate greenhouse thickness for particular uses.

Common product formats include solid sheets, twin-wall and multi-wall panels; each format’s thickness will influence heat retention, light quality and rigidity. Later sections will compare standard options such as 2–3 mm, 4–6 mm and 10–16 mm panels and explain how each suits hobby greenhouses, lean-to structures, polytunnels and commercial houses.

Sources informing this guidance include product datasheets from Palram UK and Brett Martin, horticultural advice from the Royal Horticultural Society, and relevant British Standards and manufacturer technical notes on glazing and thermal performance.

Inhaltsverzeichnis

Key Takeaways

- Polycarbonate offers a robust, lighter alternative to glass with varying insulation by thickness.

- Thermal performance, light transmission and structural strength are the main decision drivers.

- Twin-wall and multi-wall panels give better insulation than thin solid sheets.

- Best thickness polycarbonate greenhouse choice depends on climate, crop and budget.

- Consult Palram UK, Brett Martin datasheets and RHS guidance when specifying glazing.

Understanding polycarbonate for greenhouses: types and properties

This section outlines the main polycarbonate formats, their light and UV behaviour, and how thickness and construction affect heat retention. Gardeners and growers need clear comparisons to match material choice with crop needs and local climate.

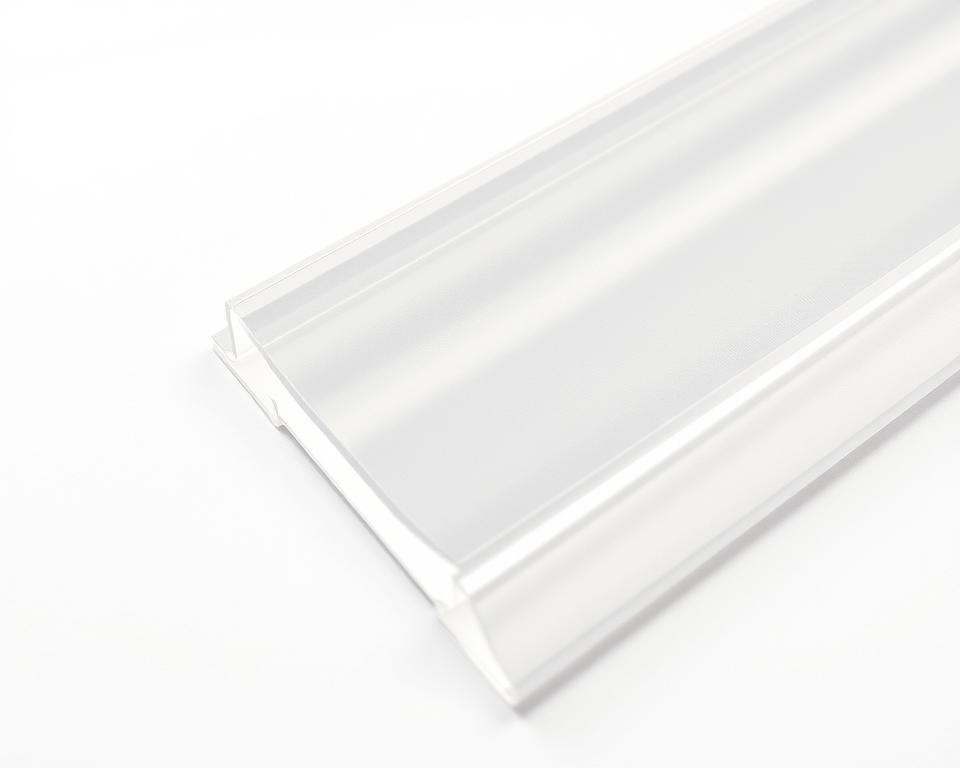

Solid, twin-wall and multi-wall formats

Solid polycarbonate is a single-sheet product that looks very like glass or acrylic. It offers high clarity and strong impact resistance, making it suitable where transparency and rigidity matter.

Twin-wall polycarbonate consists of two outer skins joined by internal ribs. The trapped air pockets give better insulation than single sheets. Typical twin-wall panels used for greenhouses are in the 4–6 mm range.

Multi-wall polycarbonate includes three or more layers with several air cavities. Thicker multi-wall panels, from around 10–16 mm, deliver increased thermal resistance and are common in colder zones or commercial structures focused on energy efficiency.

UV protection and light transmission characteristics

Reputable panels have a co-extruded UV-stabilised layer on the outer face to prevent yellowing and polymer breakdown. Manufacturers such as Palram and Brett Martin publish UV-blocking figures so buyers can check specific performance.

Visible light transmission varies by format. Solid clear sheets can transmit up to about 90% of visible light. Twin-wall panels typically range from 70% to 85%, depending on wall thickness and diffusion. Multi-wall panels commonly fall between 60% and 75%.

Surface diffusion treatments scatter incoming light to reduce hotspots and improve canopy uniformity. This helps crops by evening out light across leaves and reducing leaf scorch risks.

Thermal performance and R-values

Thermal resistance rises with the number of walls and panel thickness because additional air cavities reduce heat flow. The concept is simple: more trapped air means better insulation.

Approximate U-values show this trend. Single-layer polycarbonate has a higher U-value and poorer insulation than twin-wall. Thin twin-wall sheets can have U-values around 2.5–3.0 W/m²K. Thick multi-wall panels, such as 10–16 mm types, may reach roughly 1.6–2.0 W/m²K. Consult manufacturer datasheets for exact polycarbonate R-value and U-value figures.

Mechanical properties and handling

Polycarbonate is highly impact resistant, commonly cited as up to 200 times tougher than glass. It remains flexible compared with glass and is easier to cut and install for DIY and professional installers.

These mechanical and thermal traits make it versatile across hobby and commercial greenhouse projects. Review product datasheets from trusted brands and follow installation guidance to get the best performance for your build.

what thickness polycarbonate is best for a greenhouse?

Asking “what thickness polycarbonate is best for a greenhouse?” is common among UK gardeners. There is no single answer. Choice depends on plants, budget and how long you want the structure to perform. This section sets out evidence-based options and a practical rule of thumb.

Common thicknesses available in the UK market

The market offers a clear range. Thin 2–3 mm solid sheets suit small hobby houses and temporary covers. They are lightweight and low cost.

Mid-range 4 mm solid and 4–6 mm twin-wall panels are popular with domestic gardeners. These give a reasonable balance of light transmission and basic insulation.

Thicker 8–10 mm twin-wall and 10–16 mm multi-wall panels serve sites needing better heat retention. Many UK shops list 16 mm as a heavy-duty option for long-term glazing.

Very thick systems of 25 mm and above are used for commercial or protected cropping where insulation is crucial.

How plant type and growing objectives influence choice

Tender, light-loving crops such as tomatoes and peppers favour high PAR and brighter glazing. Clearer, thinner sheets maximise light but risk heat loss and sunscald.

Seed trays, cuttings and overwintering plants need steady warmth. Thicker multi-wall panels reduce night-time heat loss and protect against frost, improving propagation success.

Commercial growers who aim for year-round production prioritise insulation and durability. They often select 10–16 mm multi-wall panels or specialist double-glazing systems to cut fuel bills and stabilise climates.

Balancing cost, insulation and durability

Cost tends to rise with thickness. Thinner sheets are cheap to buy and simple to fit. Thicker panels increase initial outlay but lower heating demand over time.

Insulation improves with more walls and greater depth. Better R-values cut condensation and reduce the need for frequent heating, which matters on exposed UK sites.

Durability follows the same trend. Thicker panels withstand hail, impact and wind better. Warranties from brands at Wickes and B&Q often reflect panel thickness and expected life.

Practical rule of thumb for many UK buyers: choose 4–6 mm twin-wall for a domestic greenhouse. For colder locations or near-continuous cropping, consider 10–16 mm multi-wall for appreciable thermal gains.

For targeted greenhouse glazing thickness advice, compare product specifications and the Royal Horticultural Society guidance on propagation and overwintering to match requirements. Checking polycarbonate thickness UK ranges at reputable suppliers helps set realistic budgets and expectations.

Climate considerations in the United Kingdom

The UK greenhouse climate varies across regions. Most of Britain has a temperate maritime pattern with cool winters and mild summers. Scotland and northern England are colder and wetter. Southern and south‑east England enjoy more sunshine and higher summer peaks. Gardeners should match glazing and ventilation to local conditions for reliable crop performance.

Heat retention needs for colder regions

In frost‑prone areas, extra insulation reduces heating demand and protects tender plants. Home growers often choose 10–16 mm multi‑wall panels or double‑glazed systems for unheated or minimally heated structures. These thicker options rise night‑time temperatures, cut heater run times and lower energy bills when compared with thin sheets.

Ventilation and shading in sunnier areas

Even in the UK, south‑facing sites can overheat on bright days. Good ventilation design is essential; roof vents, side vents and louvres control spikes. Thicker panels with diffusive surfaces can soften direct sun and reduce hot spots, but vents remain the primary safeguard against overheating.

Snow load and wind resistance implications

Where snowfall or strong gusts are possible, choose panels and frames rated for local loads. Manufacturers publish wind and snow load figures that guide support spacing and frame selection. Multi‑wall sheets shed snow differently to single sheets, so roof pitch and support centres influence the risk of accumulation and structural stress.

Adapting a greenhouse to the UK greenhouse climate means balancing thermal performance, ventilation and structural safety. Use manufacturer data and local building guidance when planning, and factor greenhouse insulation UK into decisions for reliable year‑round growing.

Comparing thermal insulation across thicknesses

Choosing the right sheet thickness changes how a greenhouse holds heat. Polycarbonate insulation relies on trapped air between layers to slow heat flow. The number of cavities and total thickness raise the R-value and improve polycarbonate thermal performance. Below are practical comparisons to guide selection.

2–3 mm sheets: pros and cons

Thin single and solid 2–3 mm panels cost less and pass lots of light, which benefits seed trays and shade-tolerant crops. They are lightweight and easy to cut and fit for small hobby frames.

Drawbacks include poor insulation and a relatively high U-value, so heat escapes quickly. These sheets are prone to condensation and wide temperature swings, making them unsuitable for serious overwintering or heated operations.

4–6 mm twin-wall performance

4 mm and 6 mm twin-wall panels are a common domestic choice. Two layers with an air cavity give a measurable improvement in polycarbonate thermal performance. U-values fall compared with thin sheets, reducing daily heat loss and lowering heating demand.

They still have limits in very cold conditions. Growers may need supplemental heating or thermal curtains for winter propagation. Approximate comparative U-values typically range from about 3.0 W/m²K for 2–3 mm solid up to roughly 2.0–1.6 W/m²K for 4–6 mm twin-wall, depending on manufacturer details.

10–16 mm multi-wall for maximum insulation

Panels of 10–16 mm use multiple air cavities to greatly boost thermal resistance. This construction lifts R-value and cuts heat loss, which suits colder sites and long-season growing. A 16 mm multi-wall will often hold night temperatures steady and reduce heating hours.

The trade-offs are lower visible light transmission compared with thinner panels, higher initial cost and greater weight that needs stronger framing. Typical greenhouse U-value by thickness for 10–16 mm multi-wall commonly falls near 1.5–0.8 W/m²K, subject to product and testing method.

Practical examples from manufacturer thermal performance tables such as Palram and Brett Martin, plus independent glazing tests and RHS guidance, show energy savings of around 10–30% when stepping from 4 mm to 10–16 mm panels. Exact savings depend on climate, glazing quality and heating regime.

Durability and structural strength by thickness

Choosing the right polycarbonate thickness affects how a greenhouse stands up to knocks, hail and long-term wear. Thicker panels give better protection and fewer repairs. Consider both panel performance and the frame that supports it when planning a build.

Impact resistance and hail protection

Polycarbonate sheets are renowned for impact resistance. Even 4 mm twin-wall panels typically outperform glass in impact tests carried out by manufacturers such as Palram and Brett Martin. Thicker panels resist severe hail and stray branches with less risk of cracking.

Manufacturer test data for Lexan from Sabic and third‑party installer reports show that as thickness increases, energy absorption rises and the chance of perforation falls. For exposed sites, choose thicker, co‑extruded UV panels to reduce repairs and downtime.

Frame compatibility and recommended support spacing

Heavier panels need stronger frames. Aluminium and powder‑coated steel are common choices. Robust treated timber frames also work, provided fixings and sections are sized to match panel weight.

Support spacing varies by panel type and thickness. Thin sheets often need closer centres — around 300–400 mm. Mid‑range twin‑wall panels commonly suit 600 mm centres. Thick multi‑wall panels can span 600–1,000 mm subject to manufacturer guidance. Always check technical datasheets from Palram, Brett Martin or panel suppliers for exact spans and fixings.

Expected lifespan and warranty considerations

Typical service life ranges from about 10 to 20 years. UV stabilisation, co‑extrusion and environmental exposure determine longevity. Many greenhouse panels carry a 10‑year light transmission or product warranty issued by well‑known manufacturers, reflecting tested polycarbonate durability.

Thicker, UV‑protected panels show slower yellowing and longer serviceable life. For UK projects, ask for the polycarbonate warranty UK statements and clarifications on what the warranty covers. Regular maintenance helps: clean with mild detergent, avoid abrasive pads and inspect seals and fixings seasonally.

| Thickness (mm) | Typical Support Spacing (mm) | Common Frame Types | Typical Warranty |

|---|---|---|---|

| 2–3 | 300–400 | Light aluminium, timber | 5–10 years |

| 4–6 (twin‑wall) | 400–600 | Aluminium, powder‑coated steel | 8–12 years |

| 10–16 (multi‑wall) | 600–1000 | Heavy aluminium, structural steel | 10–15+ years |

Light transmission and plant growth outcomes

Choosing glazing for a greenhouse means weighing how much light reaches plants and how that light behaves once inside. Growers must consider both the quantity of usable light and its distribution across the crop. This affects yield, fruit quality and plant health.

How thickness affects PAR

PAR refers to the 400–700 nm band that plants use for photosynthesis. Not all glazing reports PAR values, so gardeners should look for PAR polycarbonate figures on technical sheets or manufacturer charts. Solid sheets tend to transmit the highest PAR per unit area. Thicker or multi-wall panels reduce absolute PAR transmission compared with thin solid sheets, but the drop is usually modest and acceptable for many crops.

Diffusion versus direct light

Diffusive glazing scatters incoming sunlight and evens out canopy illumination. This reduces hotspots and lowers the risk of sunscald on fruit.

Tight, direct light from clear panels gives higher local intensity and stronger shadows. That can boost growth in sun-loving crops but creates uneven development in dense plantings.

Twin-wall and multi-wall formats typically offer moderate greenhouse light diffusion. Specialised diffusive coatings increase scattering without a large loss in overall light. Growers of tomatoes, peppers and similar fruiting crops often see better fruit set and fewer blemishes with diffusive glazing.

Colour and clarity trade-offs

Clear solid sheets provide the best clarity and maximum polycarbonate light transmission. That suits seed raising and plants needing intense light.

Opal or frosted finishes increase diffusion but reduce total visible light transmission. Seedlings and ornamentals may prefer this soft, even light. Sun-loving vegetables can tolerate lower VLT when PAR polycarbonate transmission remains adequate.

| Glazing type | Typical PAR transmission (%) | Light behaviour | Best use |

|---|---|---|---|

| Clear solid 2–3 mm | 85–92 | Direct, high intensity, low diffusion | Seed trays, sun-loving crops, propagation |

| Twin-wall 4–6 mm | 75–85 | Moderate diffusion, good insulation | General horticulture, mixed cropping |

| Multi-wall 10–16 mm | 65–80 | Higher diffusion, reduced peak intensity | Cold climates, energy-conscious growers |

| Opal/diffuse coated sheets | 70–88 | High diffusion, softer light | Fruit crops, ornamental displays |

Cost analysis: initial outlay versus long-term savings

Choosing the right polycarbonate thickness involves more than purchase price. A modest extra spend on thicker panels can lower greenhouse running costs and extend service life. Below is a concise guide to help weigh immediate expense against future savings.

Material cost per square metre by thickness

Typical relative pricing in the UK places 2–3 mm sheets as the cheapest option, 4–6 mm twin-wall in the mid-range, and 10–16 mm multi-wall as the most expensive. Retailers such as Wickes and Jewson and specialist glazing suppliers set different rates, so exact polycarbonate cost per m2 varies by brand and supply volume.

Accessories add extra expense. Aluminium capping, end caps, thermal tape and sealant increase the initial bill. Stronger frames are often necessary for thicker panels, which raises structural costs.

Energy savings from better insulation

Thicker multi-wall panels cut heat loss and reduce heating hours in winter. Upgrading from a 4 mm twin-wall panel to a 16 mm multi-wall panel typically lowers fuel demand significantly, and that drop translates into lower greenhouse running costs over the colder months.

To illustrate, extra insulation that reduces heating hours and energy use may offset the higher polycarbonate cost per m2 across several seasons, depending on local climate and heating regime.

Maintenance and replacement cost estimates

Thicker panels usually have longer warranties and resist damage better, which reduces replacement frequency. Periodic maintenance such as cleaning, seal checks and fixing loose caps represents a predictable annual cost.

Storm damage or hail can force early replacements. Budgeting for occasional repairs helps avoid surprise spending and keeps lifecycle costs manageable.

Simple payback approach

Compare the extra upfront cost for thicker panels against projected annual heating savings and expected panel lifespan. Use retailer price checks, energy-saving case studies and lifecycle analyses from horticultural sources to populate your calculation.

Doing a basic payback polycarbonate insulation calculation shows whether the higher initial outlay is justified by reduced greenhouse running costs over the lifetime of the structure.

Installation best practice for different thicknesses

Careful planning makes installing polycarbonate greenhouse panels quick and durable. Match fixings and seals to panel thickness, follow manufacturer guidance from Palram or Brett Martin, and pay attention to orientation and movement to avoid leaks and warping.

Roof and wall fixing methods

Use manufacturer-specified screws with EPDM washers where panels meet frames. For twin and multi-wall sheets, aluminium profiles, glazing bars or capping systems provide secure support and neat finishes. Fit fixings with slotted holes or backing washers to permit thermal movement. Position the UV-stabilised face outwards; most panels carry an imprint showing correct orientation.

Sealing, end caps and condensation management

Seal channel ends with purpose-made end caps and aluminium capping to stop dust and insects entering multi-wall cavities. Apply breather tape and foam closures so trapped moisture can escape while contaminants stay out. Good ventilation and modest heating reduce internal humidity and dripping. Anti-drip or diffusive internal coatings help prevent beads forming on the underside of panels. Design roof pitch for efficient runoff to limit pooled water that worsens condensation.

Handling and cutting thicker panels safely

Cut using non-abrasive methods: a fine-tooth circular saw blade for thicker sheets, or a utility knife for thin sheets, gives clean edges. Support panels across their length to prevent cracking and edge chipping while cutting. Wear safety glasses, gloves and a dust mask. Respect minimum bending radii for flexible panels and follow supplier instructions when transporting and storing sheets.

| Task | Recommended practice | Why it matters |

|---|---|---|

| Fixing type | Manufacturer screws with EPDM washers; aluminium capping or glazing bars | Secure seal, prevents water ingress and avoids panel damage |

| Allowing expansion | Slotted holes or backing washers; leave short gaps at ends | Prevents buckling and stress fractures in changing temperatures |

| Orientation | UV-stabilised face outward, follow panel imprint | Maintains UV protection and product longevity |

| End sealing | End caps, breather tape and foam closures | Blocks pests and dust while allowing moisture to vent |

| Condensation control | Ventilation, heating, anti-drip coatings, correct roof pitch | Reduces dripping and mould risk; improves plant health |

| Cutting and handling | Fine-tooth blades, full support, PPE, follow bending limits | Clean edges, prevents cracking and protects installers |

| Guidance sources | Manufacturer installation guides (Palram, Brett Martin), glazing practice | Ensures compliance with best practice and warranty terms |

Choosing polycarbonate thickness for specific greenhouse types

Picking the right sheet thickness will affect warmth, light and longevity. Match material to purpose, budget and the support frame to get reliable results for any small or large project.

Small hobby greenhouses

For backyard growers, 4–6 mm twin-wall panels are the most common choice. They balance insulation, cost and ease of handling while giving good light for seedlings and vegetables.

Use 4 mm for summer projects and short-season use. Add a small heater for winter propagation. Very small cold frames often work well with 3–4 mm sheets when only seasonal protection is required.

Commercial and polytunnel structures

Large operations demand higher thermal performance. Multi-wall panels from 10–16 mm, or specialised systems up to 25 mm, suit year-round production and energy‑efficient glass alternatives.

Polytunnels may call for corrugated polycarbonate or heavy-duty polyethylene depending on crop rotation and scale. Check commercial greenhouse glazing specifications to ensure panels meet structural loads and light targets.

Plan integration with robust framing and mechanical ventilation or heating for consistent climate control across production cycles.

Lean-to and cold-frame applications

Lean-to structures benefit from moderate thickness, typically 4–10 mm, because the adjacent building provides extra heat retention. Thinner glazing can be acceptable when the building supplies most of the thermal mass.

Cold frames commonly use cold frame polycarbonate in the 3–6 mm range or horticultural glass for seasonal use. Choose thicker panels when overwintering tender plants to reduce heat loss and limit frost risk.

Decision matrix for quick selection:

- Smallest budget / short-season usage: 2–4 mm

- General hobby / year-round ambition: 4–6 mm

- Cold climates / commercial production: 10–16 mm or more

Refer to RHS guidance and manufacturer glazing specifications when finalising choices. Practical case studies from growers help confirm how different thicknesses perform in real conditions.

Common mistakes and how to avoid them

Choosing polycarbonate for a greenhouse is more than picking a thickness. Many gardeners face preventable greenhouse mistakes that cut performance and raise costs. Below are practical checks to keep a project on track.

Underestimating structural loads

Selecting thin panels without checking wind and snow load ratings causes failures. Check manufacturer load tables from brands such as Palram or Brett Martin and match panel choice to frame strength. Use closer support spacing where wind exposure or snowfall risk is high. Consult building regulations if the structure is attached to a property.

Choosing thickness solely on price

Opting for the cheapest option can raise lifetime costs. Thinner sheets may need replacing sooner, increase heating bills and harm sensitive crops. Compare lifecycle cost, warranty length and thermal performance before buying. A slightly thicker sheet often delivers better insulation and value over several seasons.

Poor ventilation and overheating

Relying on glazing alone to control temperature causes greenhouse ventilation problems. Fit a mix of roof vents, louvre vents and automatic vent openers from reliable suppliers. Add shade cloth or diffusive glazing where sun intensity is high. Monitor temperature and humidity with simple sensors to protect plants.

Additional common pitfalls

- Installing panels the wrong way round can void warranties. Follow manufacturer markings to keep the UV face outward.

- Poor sealing invites insects and condensation. Use end caps, breather tape and correct capping profiles to avoid gaps.

- Incorrect fasteners or excessive compression cause polycarbonate installation errors. Use recommended screws with EPDM washers and follow torque guidance.

Consult RHS guidance on greenhouse environmental control and follow installer advice for compliance. Taking these steps reduces common greenhouse mistakes and minimises polycarbonate installation errors while addressing greenhouse ventilation problems early.

Where to buy and what to look for in suppliers

Choosing the right supplier affects performance and peace of mind. Start by checking national DIY retailers such as Wickes and B&Q, specialist glazing merchants, horticultural outlets and manufacturers like Palram UK and Brett Martin. Online marketplaces such as Toolstation and dedicated polycarbonate merchants offer wide stock lists. Local builders’ merchants may carry common panel sizes for immediate collection.

Reputable sellers will supply clear technical information. Ask for datasheets that list thickness, co-extruded UV layer, light transmission (VLT/PAR), U-value, impact resistance and load ratings. Confirm CE marking or compliance with relevant British and European standards. Read manufacturer warranty terms that cover light transmission and product integrity over time.

Requesting samples helps judge clarity and diffusion before a bulk order. Visit showrooms where possible to handle panels and inspect edge finish and fitment. Ask for SDS (safety data sheets), installation guides and orientation marking so you can match panels to your frame and support spacing.

Use a simple checklist when comparing suppliers:

- Availability of technical datasheets and warranty documents.

- Samples or showroom access for visual inspection.

- Transparent delivery times and cut-to-size services.

- Verified customer reviews and trade references.

For technical certainty, consult three sources. First, supplier product pages and customer feedback. Second, manufacturer technical and warranty documentation from firms such as Palram UK or Brett Martin. Third, trade associations and independent buying guides for glazing materials.

If you need to buy polycarbonate sheets UK in bulk, contact multiple polycarbonate suppliers UK for quotes and lead times. For greenhouse installations, check with greenhouse glazing suppliers who can advise on profile compatibility and installation accessories.

Conclusion

There is no single best choice; the final recommendation polycarbonate thickness depends on climate, crop, budget and whether you need year‑round performance. For most domestic gardeners in the UK, 4–6 mm twin‑wall panels offer the best compromise of insulation, light transmission and cost. They suit seasonal growing and many overwintering needs while remaining easy to install.

For colder sites, commercial production or serious overwintering, choose 10–16 mm multi‑wall sheets for superior thermal performance and durability. If the greenhouse is temporary or only for summer use, 2–3 mm can be acceptable but expect greater heat loss and a shorter lifespan. These options reflect manufacturer data, RHS guidance and typical UK climate demands.

Installation matters as much as thickness. Use correct fixings, fit the UV face outward, install end caps and breather tape, and buy from reputable UK suppliers with clear datasheets and warranty. Before you decide, compare manufacturer datasheets, request samples where possible and perform a simple payback calculation to choose the most cost‑effective option when you choose polycarbonate greenhouse thickness.

FAQ

What is polycarbonate and why is it used for greenhouse glazing?

Polycarbonate is a lightweight, impact‑resistant thermoplastic used as an alternative to glass and horticultural polyethylene. It offers excellent toughness, good light transmission and the ability to be formed in solid, twin‑wall and multi‑wall formats. These formats provide varying balances of clarity, insulation and diffusion, making polycarbonate a popular choice for hobby greenhouses, allotments and commercial growing where durability and thermal performance matter.

Which polycarbonate formats are available and how do they differ?

The main formats are solid sheets, twin‑wall (double‑wall) and multi‑wall panels. Solid sheets give the highest clarity and are used when transparency is the priority. Twin‑wall panels have two skins separated by ribs, trapping air for improved insulation and are common in 4–6 mm sizes. Multi‑wall panels (10–16 mm and above) contain multiple cavities for greater thermal resistance, suited to cold sites and commercial operations.

How does thickness affect thermal performance (U‑value/R‑value)?

Thermal resistance improves with additional layers and thickness because trapped air cavities reduce heat loss. Thin single‑layer sheets have comparatively high U‑values and poor insulation. Typical ranges are higher U‑values for single layers, around 2.5–3.0 W/m²K for thinner twin‑wall products, and approximately 1.6–2.0 W/m²K for 10–16 mm multi‑wall panels, although exact figures vary by manufacturer and product.

What thickness is generally best for a domestic greenhouse in the UK?

For most domestic gardeners, 4–6 mm twin‑wall polycarbonate represents the best compromise. It balances visible light transmission, reasonable thermal performance and cost, and is easy to handle for hobby structures. In warmer southern sites or for seasonal use, 4 mm may suffice; for overwintering or colder locations, thicker panels are preferable.

When should I choose 10–16 mm multi‑wall panels?

Choose 10–16 mm multi‑wall panels if you need superior insulation for overwintering, propagation or near‑year‑round production. These panels provide better R‑values, reduced heating hours and more stable night temperatures. They are common for cold sites, commercial greenhouses and situations where long‑term energy savings and reduced condensation are priorities.

Are there trade‑offs between light transmission and insulation?

Yes. Thicker and multi‑layer panels typically transmit slightly less visible light and PAR than thin solid sheets. However, multi‑wall panels often provide useful diffusion that improves canopy light distribution. Clear solid sheets give the highest VLT (up to ~90%), twin‑wall typically 70–85% and multi‑wall often 60–75%, depending on finish and manufacturer.

How does diffused glazing affect plant growth?

Diffusive glazing scatters sunlight, reducing hotspots and improving uniformity across the canopy. This benefits fruiting crops such as tomatoes and peppers by lowering sunscald risk and aiding even development. Seedlings and ornamentals often thrive under more diffuse light. If maximum direct intensity is needed, clear solid glazing will provide that, but may create local overheating.

What about UV protection and panel longevity?

Reputable greenhouse panels include a co‑extruded UV‑stabilised layer on the outer face to prevent yellowing and polymer degradation. Manufacturers such as Palram and Brett Martin provide technical data on UV blocking and expected light transmission retention. Co‑extruded UV panels typically carry product warranties (commonly around 10 years) and can last 10–20 years depending on conditions and maintenance.

How do snow load and wind affect thickness choice and frame design?

Thicker panels offer greater structural resilience to snow and hail. However, the overall performance depends on frame strength, support spacing and roof pitch. Manufacturers publish wind and snow load ratings; follow these and local building guidance. In snow‑prone areas consider multi‑wall panels with stronger framing and reduced span spacing to prevent overload.

Can I retrofit thicker polycarbonate into an existing greenhouse frame?

Possibly, but check frame compatibility and support spacing first. Thicker panels are heavier and may require stronger glazing bars or closer supports. Consult manufacturer technical datasheets for recommended fixing systems and maximum spans. If in doubt, reinforce or upgrade the frame to meet the panel’s load requirements.

What fixing and sealing practises should I follow for polycarbonate panels?

Use manufacturer‑specified screws with EPDM washers, aluminium capping or glazing bars, and allow for thermal expansion with slotted holes or backing washers. Fit end caps and breather tape to twin/multi‑wall ends to prevent dust and insect ingress while allowing moisture to escape. Ensure the UV‑stabilised face is orientated outwards as marked on the panel.

How do I manage condensation inside multi‑wall panels?

Good ventilation and appropriate heating reduce internal condensation. Use end caps with breather tape to control moisture in the cavities, and ensure sufficient roof pitch and airflow. Anti‑drip internal coatings and careful siting of vents also help manage humidity and prevent dripping onto plants.

What are typical costs and how do I assess payback for thicker panels?

Material cost rises with thickness: 2–3 mm is the cheapest, 4–6 mm moderate, and 10–16 mm more expensive. Also allow for stronger frames, capping and seals. Estimate annual heating savings from improved insulation and compare these against the extra upfront cost over the panel’s expected life to calculate payback. Retailers such as Wickes, B&Q and specialist glazing suppliers can provide current pricing for accurate calculations.

Are there common mistakes buyers make when choosing thickness?

Yes. Common errors include underestimating wind/snow loads, choosing solely on price without lifecycle costing, incorrect orientation of the UV face and poor ventilation planning. Avoid these by checking manufacturer load tables, warranties and technical datasheets, and by ensuring the greenhouse design includes adequate vents and shading where necessary.

Which suppliers in the UK are recommended and what should I request from them?

Purchase from established retailers and manufacturers such as Palram UK, Brett Martin, national DIY chains (Wickes, B&Q) or specialist polycarbonate merchants. Request technical datasheets, PAR/VLT and U‑value figures, warranty terms, SDS and installation guides. Ask for samples where possible to assess clarity, diffusion and handling before committing to bulk orders.

How should I cut and handle thicker panels safely?

Use the appropriate cutting tools: fine‑tooth circular saws for thick panels, utility knives for thin sheets and recommended blades to avoid chipping. Wear PPE—safety glasses, gloves and dust masks—and support panels fully while cutting. Observe minimum bending radii on flexible sheets and follow manufacturer guidance to avoid damage.

For which greenhouse types are different thicknesses most suitable?

Small hobby greenhouses typically suit 4–6 mm twin‑wall. Very small cold frames or short‑season structures can use 2–4 mm. Commercial greenhouses and year‑round protected cropping usually benefit from 10–16 mm multi‑wall or specialised thicker systems. Lean‑to greenhouses attached to heated buildings may perform well with moderate thickness (4–10 mm) because of the building’s thermal mass.

Will thicker polycarbonate panels increase my crop yields?

Thicker panels themselves do not directly increase yields, but they improve thermal stability, reduce frost risk and can improve light diffusion. These factors can support better fruit set, reduced stress and more consistent growing conditions, which often translate into improved crop performance when combined with appropriate ventilation, heating and crop management.